Cip cleaning

Clean-In-Place (CIP)

CIP cleaning is traditionally a cleaning process that requires a lot of water, chemicals and energy. In many hygiene-critical productions, such as the food and pharmaceutical industries, it is also necessary to disinfect the production system after CIP cleaning has been completed, which in turn requires using additional water and chemicals.

With Anolytech’s environmentally friendly disinfection system, no harmful chemicals are needed in the disinfection stage. Large amounts of water and energy can be saved at the same time.

Effective and environmentally smart

Anolytech’s disinfectant solution AnoDes is made on site from only water, salt and electricity and therefore does not use harmful chemicals. Treating tanks, pipes and valves with hot water becomes unnecessary with Anolytech’s system, which saves energy.

Since AnoDes effectively kills microorganisms without leaving any harmful residues behind, there is no need for post-rinsing, thus saving large amounts of water. Add to that the fact that the CIP process takes less time, allowing for faster production start-up.

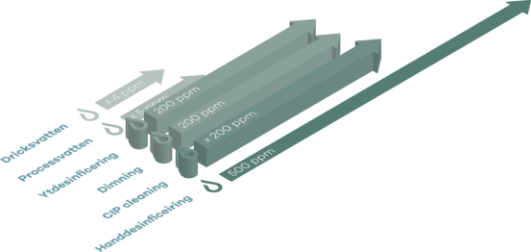

Dosage strengths for anodes

Circular process

Relevant links

Dosage strengths for anodes