Hygiene is crucial in an industry where large quantities of fresh fish are handled daily. Listeria and other bacteria are a constant challenge in the fish industry, and to minimize the risk of contamination, Firda Seafood Group has been collaborating with Anolytech for nearly 11 years. By using Anolytech’s solution, they have ensured bacteria-free water in several parts of their production.

A Leading Producer of Fjord Trout

Firda Seafood Group is a family-owned company and one of Norway’s largest producers of fjord trout. They operate both fish farming and further processing, with a modern facility handling the entire chain – from reception and slaughter to processing and packaging. Since 2020, the company has focused entirely on fjord trout in its farming, but the slaughterhouse also processes salmon. Firda Seafood Group continuously works to optimize its processes for quality and food safety.

Firda Seafood Group is a family-owned company and one of Norway’s largest producers of fjord trout. They operate both fish farming and further processing, with a modern facility handling the entire chain – from reception and slaughter to processing and packaging. Since 2020, the company has focused entirely on fjord trout in its farming, but the slaughterhouse also processes salmon. Firda Seafood Group continuously works to optimize its processes for quality and food safety.

Bacteria-Free Water Throughout the Process

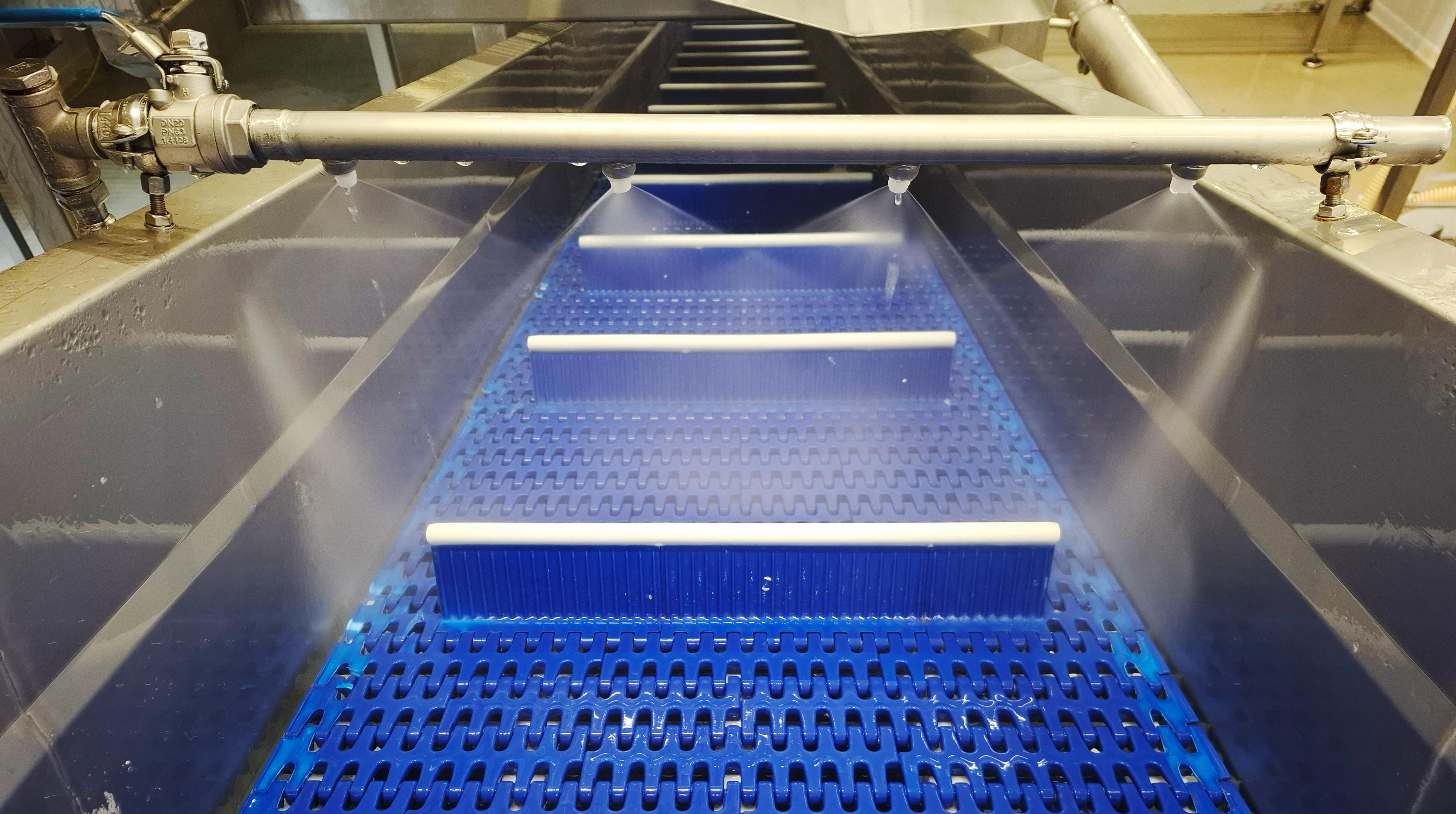

To ensure high hygiene standards and reduce the risk of bacterial growth in waterborne systems, Firda Seafood Group has been using Anolytech’s system for over a decade. Anolytech’s solution is integrated at strategic points in the production chain, including conveyor belts, sorting stations, slaughter machines, and ice machines.

A particular challenge in the fish industry is ice machines, which are known to be breeding grounds for bacteria if not properly cleaned. Ice is used both to cool the fish during transport and to maintain the correct temperature during storage. Firda Seafood Group produces up to 50 tons of ice per day, and it is crucial that the ice is free from bacteria to prevent contamination of the fish.

“We have used Anolytech’s solution for many years and see that it helps us keep bacterial levels consistently low,” says Halvor Johan Steine, mechanic and maintenance manager at Firda Seafood Group.

How Anolytech’s Solution Works

To ensure bacteria-free water throughout the production process, pH-optimized hypochlorous acid, called AnoDes, is produced on-site at the customer’s facility. By adding a small amount of AnoDes to the water system, continuous disinfection is ensured without affecting the water’s properties.

The solution works by:

- Eliminating bacteria such as Listeria, E. coli, and Legionella without creating resistance.

- Being gentle on staff and equipment due to its non-corrosive composition.

- Being produced on-site, eliminating the need to handle or store hazardous chemicals.

AnoDes is automatically dosed into the water and distributed throughout the production system, including ice machines and conveyor belts. This ensures consistent and effective disinfection without the need for manual application or traditional chemicals.

Results and Improvements

After using Anolytech’s system for an extended period, Firda Seafood Group has seen clear improvements in its production process. Thanks to continuous disinfection, bacterial levels remain low, reducing the risk of fish contamination. Regular tests show that Listeria and other bacteria remain at a consistently low level throughout the production day, providing increased safety both internally and for the end customer.

The effectiveness of Anolytech’s solution has been confirmed over the years. When Halvor was asked what he thought would happen if they removed the system, his response was clear:

“We have tested what happens if we remove disinfection in certain parts of the process, and we’ve seen that bacterial levels rise quite quickly. I believe we would notice a negative effect almost immediately if we stopped using the system. It would definitely impact our hygiene standards and require more manual work,” he says.

In addition to maintaining low bacterial levels, automating the disinfection process has made cleaning more efficient. Previously, more manual effort was required to uphold high hygiene standards in water and cooling systems. Now, disinfection happens continuously, reducing the need for extensive cleaning stoppages.

Continued Development of Water Purification and Bacteria Control

Firda Seafood Group is always open to improving more processes with bacteria-free water and maintains an ongoing dialogue with Anolytech. They are now evaluating the possibility of connecting additional conveyor belts and new collection stations currently under construction.

“We see that there are more areas where we can use this technology, especially in parts of the facility where we are now rebuilding and updating machinery,” continues Halvor Johan Steine.

With over a decade of positive experiences with Anolytech’s solution, Firda Seafood Group looks forward to continuing the collaboration to further strengthen food safety and streamline its processes.

“I would absolutely recommend Anolytech to other companies in the industry. We have always received great support, and their technicians are knowledgeable and helpful on-site,” says Halvor Johan Steine.