Bacteria-free water is essential for businesses across industries, whether it’s for drinking water systems, industrial processes, or recycled wastewater. Traditional disinfection methods often rely on harmful chemicals, leading to environmental concerns and operational challenges.

Anolytech offers a revolutionary solution with AnoDes – a sustainable disinfectant produced on-site using only water, salt, and electricity. AnoDes provides continuous disinfection, eliminates bacteria, and prevents biofilm buildup, ensuring 24/7 bacteria-free water. Fully compliant with EU standards and requiring minimal maintenance, Anolytech delivers a reliable and efficient way to secure safe water for your operations.

Our system excels in a variety of contexts. Whether you’re managing industrial process water, ensuring Legionella-free showers in public facilities, or providing bacteria-free drinking water, Anolytech offers proven solutions.

Ensure safe, bacteria-free water for consumption by both humans and livestock.

Proactively prevent Legionella outbreaks and effectively eliminate bacteria in critical water systems

Ensure bacteria-free water in industrial processes and prevent biofilm without the use of harmful chemicals.

Recycle wastewater intobacteria-free technical water with Anolytech’s sustainable solution.

Anolytech’s solution effectively eliminates bacteria, viruses, spores, mold, and fungi, while also stopping the growth of biofilm in water systems. With AnoDes, your water system stays bacteria-free 24/7, providing a safe and reliable solution for diverse applications, from drinking water to industrial processes.

Produced using only water, salt, and electricity, AnoDes is completely safe for humans and animals. Its environmentally friendly composition breaks down into 99.5% water and 0.5% biodegradable substances, leaving no harmful chemical residues. With AnoDes, there’s no need for protective gear or complex handling procedures, making it a safer alternative for users and the planet.

Unlike traditional methods that require downtime or periodic interventions, Anolytech’s system delivers continuous protection. AnoDes is produced on-site and automatically added to your water system, providing uninterrupted disinfection. This proactive approach prevents bacterial growth and biofilm formation, ensuring optimal safety and operational efficiency at all times.

By eliminating the need for frequent chemical treatments and manual cleaning, Anolytech’s system significantly reduces operational costs. The on-site production of AnoDes means you always have a fresh supply of disinfectant, without the need for costly logistics or storage. The system is designed for simplicity, requiring minimal maintenance from your team.

Anolytech’s solution complies with European standards, including multiple EN certifications and approval under the European Chemicals Agency’s (ECHA) Biocidal Products Regulation (Article 95). These certifications ensure that AnoDes is both safe and effective for a wide range of applications, from drinking water systems to industrial processes. By meeting stringent EU regulations, Anolytech helps businesses maintain compliance while delivering reliable, bacteria-free water disinfection.

Anolytech’s disinfection system reflects the innovation and reliability of Swedish engineering. Developed and manufactured in Sweden, it meets the highest standards of quality and sustainability, ensuring robust, long-term solutions for bacteria-free water.

Anolytech’s solution effectively eliminates bacteria, viruses, spores, mold, and fungi, while also stopping the growth of biofilm in water systems. With AnoDes, your water system stays bacteria-free 24/7, providing a safe and reliable solution for diverse applications, from drinking water to industrial processes.

Produced using only water, salt, and electricity, AnoDes is completely safe for humans and animals. Its environmentally friendly composition breaks down into 99.5% water and 0.5% biodegradable substances, leaving no harmful chemical residues. With AnoDes, there’s no need for protective gear or complex handling procedures, making it a safer alternative for users and the planet.

Unlike traditional methods that require downtime or periodic interventions, Anolytech’s system delivers continuous protection. AnoDes is produced on-site and automatically added to your water system, providing uninterrupted disinfection. This proactive approach prevents bacterial growth and biofilm formation, ensuring optimal safety and operational efficiency at all times.

By eliminating the need for frequent chemical treatments and manual cleaning, Anolytech’s system significantly reduces operational costs. The on-site production of AnoDes means you always have a fresh supply of disinfectant, without the need for costly logistics or storage. The system is designed for simplicity, requiring minimal maintenance from your team.

Anolytech’s solution complies with European standards, including multiple EN certifications and approval under the European Chemicals Agency’s (ECHA) Biocidal Products Regulation (Article 95). These certifications ensure that AnoDes is both safe and effective for a wide range of applications, from drinking water systems to industrial processes. By meeting stringent EU regulations, Anolytech helps businesses maintain compliance while delivering reliable, bacteria-free water disinfection.

Anolytech’s disinfection system reflects the innovation and reliability of Swedish engineering. Developed and manufactured in Sweden, it meets the highest standards of quality and sustainability, ensuring robust, long-term solutions for bacteria-free water.

AnoDes is a pH-optimized hypochlorous acid produced on-site using only water, salt, and electricity. This environmentally friendly and safe disinfectant effectively eliminates bacteria, viruses, spores, mold, and fungi, and prevents biofilm growth in water systems. Its neutral pH (around 6.5) ensures a high bactericidal effect with minimal salt content. AnoDes complies with European disinfectant standards and is approved under Article 95 of the Biocidal Products Directive.

Anolytech’s system offers a groundbreaking approach to sustainable water disinfection. By using only water, salt, and electricity, the process eliminates the need for harmful chemicals, ensuring a safer solution for both the environment and users.

The benefits extend beyond disinfection. With no dangerous chemicals involved, transports of dangerous goods are reduced, and the minimal packaging reduces waste. Residual products are so harmless that they can safely be released into the drain.

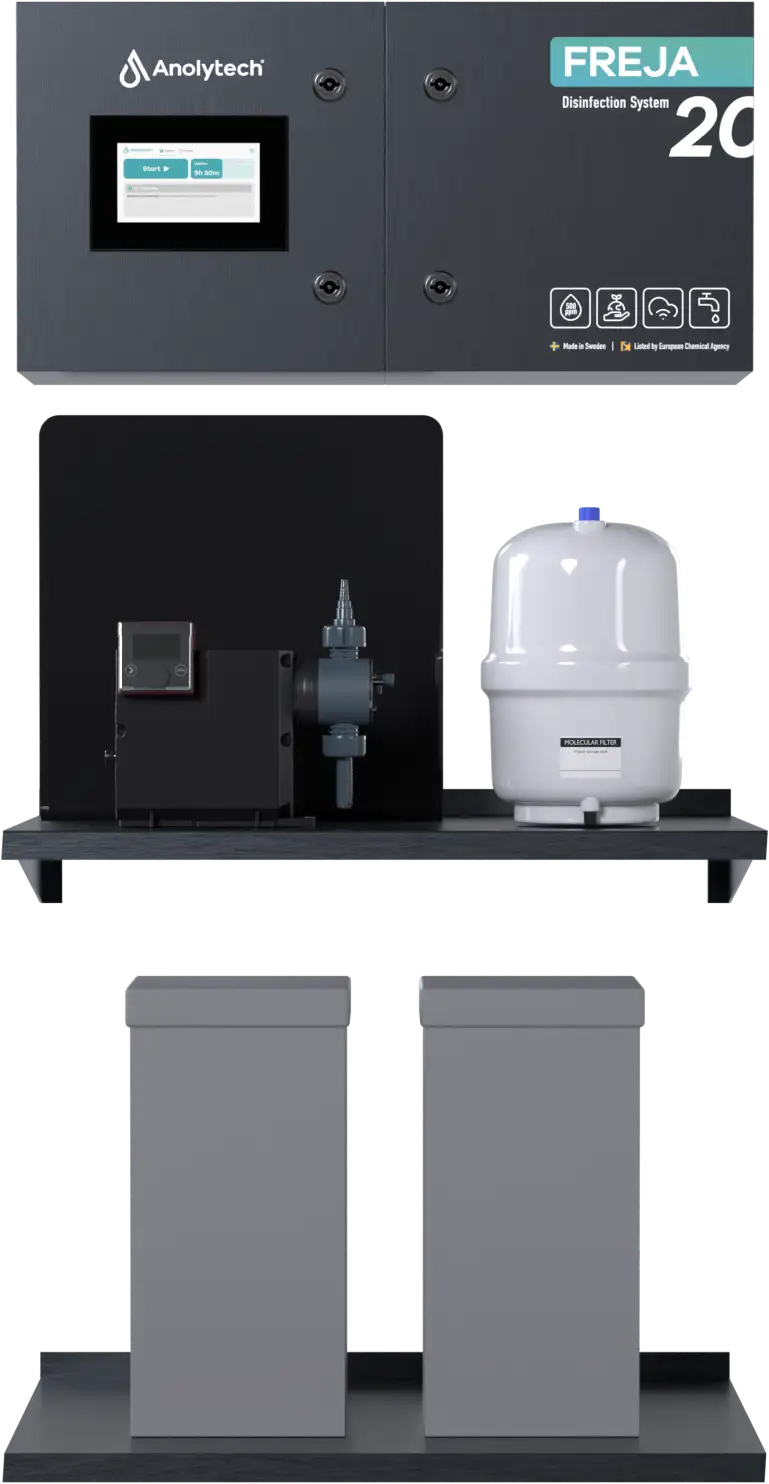

Anolytech’s system integrates seamlessly into your existing water infrastructure. With three machine sizes available, the solution is designed to meet the unique needs of businesses across industries, from smaller operations to large-scale facilities.

Minimal disruption during setup; connects directly to your water system.

Designed for simplicity, requiring minimal oversight from your team.

Automatically doses precise amounts of AnoDes into your water system for continuous disinfection.

Chemical disinfectants and antiseptics – Hygienic hand sanitiser.

Quantitative suspension test for evaluating the bactericidal action of chemical disinfectants and antiseptics for use in food, industrial, home, and institutional settings.

Quantitative suspension test for evaluating the virucidal activity against bacteriophages of chemical disinfectants used in food and industrial settings.

Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity in the medical area.

Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems.

Chemical disinfectants and antiseptics – Quantitative non-porous surface test for the evaluation of bactericidal and/or fungicidal activity of chemical disinfectants used in food, industrial, domestic, and institutional areas.

Quantitative suspension test for the evaluation of bactericidal activity in the medical area, with good results on e.g., Salmonella.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating the antibacterial effect of chemical disinfectants used in veterinary settings on non-porous surfaces without mechanical action.

Quantitative suspension test for the evaluation of virucidal activity in the medical area. Tested on several viruses and the coronavirus group of viruses.

Quantitative carrier test for evaluating the bactericidal effect of chemical disinfectants for instruments used in healthcare.

Quantitative carrier test for evaluating the fungicidal and yeasticidal effect of chemical disinfectants for instruments used in healthcare.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the virucidal effect of chemical disinfectants and antiseptics in veterinary applications.

Quantitative suspension test for evaluating the fungicidal action of chemical disinfectants and antiseptics for use in food, industrial, home, and institutional settings.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the antibacterial effect of chemical disinfectants and antiseptics for use in veterinary settings.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the fungicidal and yeasticidal effect of chemical disinfectants and antiseptics in veterinary settings.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating the fungicidal and yeasticidal effect of chemical disinfectants used in veterinary settings on non-porous surfaces without mechanical action.

Chemical disinfectants and antiseptics – Quantitative test for non-porous surfaces without mechanical activity to evaluate the virucidal effect of chemical disinfectants in medical environments.

Quantitative carrier test for airborne room disinfection by automated processes.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating disinfectants used for teat disinfection in veterinary settings.

Chemical disinfectants and antiseptics – Hygienic hand sanitiser.

Quantitative suspension test for evaluating the bactericidal action of chemical disinfectants and antiseptics for use in food, industrial, home, and institutional settings.

Quantitative suspension test for evaluating the virucidal activity against bacteriophages of chemical disinfectants used in food and industrial settings.

Quantitative suspension test for the evaluation of fungicidal or yeasticidal activity in the medical area.

Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems.

Chemical disinfectants and antiseptics – Quantitative non-porous surface test for the evaluation of bactericidal and/or fungicidal activity of chemical disinfectants used in food, industrial, domestic, and institutional areas.

Quantitative suspension test for the evaluation of bactericidal activity in the medical area, with good results on e.g., Salmonella.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating the antibacterial effect of chemical disinfectants used in veterinary settings on non-porous surfaces without mechanical action.

Quantitative suspension test for the evaluation of virucidal activity in the medical area. Tested on several viruses and the coronavirus group of viruses.

Quantitative carrier test for evaluating the bactericidal effect of chemical disinfectants for instruments used in healthcare.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the virucidal effect of chemical disinfectants and antiseptics in veterinary applications.

Quantitative suspension test for evaluating the fungicidal action of chemical disinfectants and antiseptics for use in food, industrial, home, and institutional settings.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the antibacterial effect of chemical disinfectants and antiseptics for use in veterinary settings.

Chemical disinfectants and antiseptics – Quantitative suspension test for evaluating the fungicidal and yeasticidal effect of chemical disinfectants and antiseptics in veterinary settings.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating the fungicidal and yeasticidal effect of chemical disinfectants used in veterinary settings on non-porous surfaces without mechanical action.

Chemical disinfectants and antiseptics – Quantitative test for non-porous surfaces without mechanical activity to evaluate the virucidal effect of chemical disinfectants in medical environments.

Quantitative carrier test for airborne room disinfection by automated processes.

Chemical disinfectants and antiseptics – Quantitative surface test for evaluating disinfectants used for teat disinfection in veterinary settings.

The product is approved for use in accordance with The ECHA Article 95 list.

Disinfectant for human hygiene

Disinfectants and algicides not intended for direct use in humans

or animals

Disinfectant for veterinary hygiene

Disinfectant for surfaces that come into contact with food and animal feed

Disinfectant for drinking water for humans and animals

Disinfectants for cooling towers and technical water

The use of electrolysed water in organic production is approved by the EU. The EU Expert Group on Organic Production (EGTOP) has recognised hypochlorous acid, produced on-site with equipment like Anolytech’s, as a suitable disinfection method.

No, our machine produces AnoDes on site, which is then dosed in small quantities into the water system. The water itself never passes through the machine.

In some cases, a faint chlorine odor may occur when chlorine compounds react with organic matter such as bacteria or biofilm. This odor diminishes as the bacteria and biofilm are eliminated. However, the water is perfectly safe to drink, and Anolytech follows all the rules for dosing in drinking water.

Anolytech's system is designed for simplicity and requires minimal maintenance. The main tasks are to regularly refill salt and change filters. These simple steps ensure that the system works optimally, and our team is available for support if needed.

Anolytech's solution offers continuous, preventive protection by dosing AnoDes directly into the water system. Unlike traditional methods that rely on harmful chemicals or reactive treatments, AnoDes is produced on-site using only water, salt and electricity. This ensures sustainable, safe and effective disinfection without harmful by-products.

Fill out the form, and one of our team members will get back to you as soon as possible. We’re happy to assist and would love to discuss how we can help with your disinfection needs—maybe even over a cup of coffee!

Our Solution The disinfection system & AnoDes Sustainable water disinfection with Anolytech Bacteria-free water is essential for businesses across industries, whether it’s for drinking water systems, industrial processes, or recycled […]